3D technique changes traditional building production way

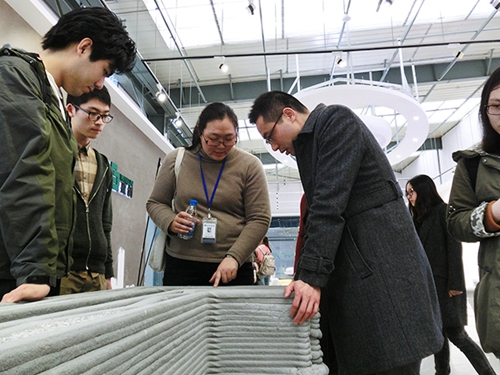

What does a 3D printed house look like? Last weekend, teachers and students of department of architecture of Xi'an Jiaotong-Liverpool University visited Suzhou industrial park of Yingchuang Building Technique Co.,Ltd ( hereinafter refers to Yingchuang) and saw 3D printing building by their own eyes, further understanding the high technology of China architecture..

China is the world's largest consumer of cement by far. China's architectural culture is widely criticized for its extensive use of reinforced concrete. Recently, Suzhou industrial park of Yingchuang Building Technique Co.,Ltd near Xi'an Jiaotong-Liverpool University has been paid international attention by successfully printed a series of concrete buildings using the innovative 3D printing technology developed by them.

The relevant personnel of Yingchuang company introduced the company's history and new technology to the teachers and students of Xi'an Jiaotong-Liverpool University. “ Yingchuang is committed to materials innovation and develops special concrete ink by traditional materials, such as GRG, FRP, making 3D printing architecture possible.” This not only solves the problem of heteromorphic decoration in large construction projects, but also greatly improves the efficiency and saves the building materials and reduces the construction cost. It is worth mentioning that the "ink" materials used in 3D printing are mainly recycled construction waste, cement and steel, and some special auxiliaries. After the building materials are printed in the factory, the building components will be transported to the assembly site, which will greatly reduce the time and effort required to meet the traditional cast-in-place concrete structures.

Yingchuang company is not only committed to the development of new technologies, but takes it into practice, focusing on the R&D of large and continuous 3D printer and printing oil and becoming the leader of 3D printing application field, which is the world first high-tech enterprise that truly achieves 3D printing architecture.

In the sample room, the teachers and students of the architecture department visited the unique layered structure produced by the concrete printing and observed several buildings at close range, including the world first integrated 3D printing “1,100 square meters of hardback villa" and the world's first 3D printed six-story, 15-meter-high residential building.

New technologies such as 3D printing, developed by the company, have upended traditional architecture and brought new prospects to architecture, which also inspired the architecture students' imagination to China and the world's future buildings.

March 24, 2015 From: Huayu Education net