3D printing application field

In 2014, Yingchuang has printed the first house that can be printed. In 2016, the world's first 3D printing office officially settled in Dubai. UAE vice President and prime minister sheikh Mohammed bin rashid al-maktoum unveiled the world's first 3D printing office in Dubai. "A drawing, a button can print the house directly." The futuristic components, interior furniture and all the details of the office are printed on one floor and one floor by a large 3D printer developed by Yingchuang Building Technique ( Shanghai ) Co.,Ltd. The 3d-printed office covers an area of 250 square meters and takes 19 days to complete. The design concept is to realize the transformation from the traditional work environment to the future office environment, and the water, electricity and communication in the building are all available. The printing will be specially reserved for water and electricity pipelines, so the printed office can be delivered directly to use.

Yingchuang Architecture focuses on 3D printing new green building, committed to creating the world's largest ecological platform for win-win industry alliance. Focus on developing large, continuous 3D printers and printing inks, and become a leader in the field of 3D printing applications. Change construction, building materials decoration, traditional manufacturing to environmental damage. The thirteenth year dream of Winsun is to make the sky bluer, water clearer, the mountain greener and the world more beautiful, committed to become a respectable company!

Aerospace science and technology

NASA is expected to complete its first imaging telescope at the end of September 2014. All components are basically made by 3D printing technology. NASA became the first company to attempt to make the entire instrument using 3D printing technology.

On August 31, 2014, NASA engineers had just completed a test of a 3D printed rocket ejector. This study aims to improve the performance of a component of a rocket engine. Because the liquid oxygen in the injector is mixed with gaseous hydrogen, the combustion temperature here can reach 6000 degrees Fahrenheit, or about 3,315 degrees Celsius, which can produce 20,000 pounds of thrust, about 9 tons, the feasibility of 3D printing technology in rocket engine manufacturing is verified. The test was conducted at NASA's Marshall space flight center in huntsville, Alabama. There is a perfect test condition for the rocket engine, and the engineers can verify the performance of 3D printing parts in the ignition environment.

On October 11, 2014, a team of British enthusiasts made a rocket using 3D printing technology. They are also ready to launch the world's first printed rocket. The team introduced the world's first 3D printing technology to the media at its London office. Team captain haines says it is not difficult to create highly complex shapes with 3D printing. Even if you want to modify the design prototype, the printer will make relative adjustments as long as it is modified on the computer aided design software. This is much more convenient than the traditional way of making things. Now that NASA is using 3D printing technology to make rocket parts. The prospects for 3D printing are bright.

Medical Industry

3D printing of liver models

The research team of Tsukuba university and the Japanese printing company of Japan announced on July 8, 2015, they have developed a method to make a three-dimensional model of the liver with a 3D printer that can see the internal structure of blood vessels. It is said that the method can be used to make models for each patient, helping to confirm the order of operation before surgery and to explain the treatment to patients.

3D printing of vertebrae implanted in the human body

In August 2014, the Peking University research team successfully implanted a 3D printed spine for a 12-year-old boy, the first case in the world. It is understood that the young boy's spine developed a malignant tumor after a football injury. Doctors had to choose to remove the spine from the tumor. This time, however, it is unusual for doctors to try advanced 3D printing techniques instead of traditional spine transplants. Researchers say the implants can be very well combined with existing bones, and can shorten the patient's recovery time. Because the implanted 3D spine is well aligned with the surrounding bones, it does not require much "anchoring". In addition, researchers have created microholes that help the bones grow between the alloys. In other words, a 3D printed spine that is implanted will be firmly rooted in the original spine. This also means that there will be no looseness in the future.

3D printing palm to treat disability

In October 2014, doctors and scientists used 3D printing technology to hold the palms of a five-year-old girl in Scotland. When she was born, her left arm was disabled, with no hands, only wrists. With the cooperation of doctors and scientists, she designed a special prosthesis and successfully installed it.

3D-printed heart resuscitated 2 weeks old heart disease baby

On October 13, 2014, Dr.EmileBacha, a doctor at New York Presbyterian hospital, told the story of a 2-week-old baby with a 3D printed heart. The baby has a congenital heart defect that creates a "massive hole" inside the heart. In the past, this type of surgery needed to stop the heart, open it up and observe it, and then in a very short time decide what to do next. But with 3D printing, Dr. Barcha can make a model of the heart before the surgery. This allows his team to examine it and decide what to do during the operation. The baby was supposed to have three to four operations, and once is enough. The baby, originally believed to have a limited life span, could lead a normal life.

3D printing pharmacy

On August 5, 2015, the first batch of SPRITAM (levetiracetam) prepared by Aprecia pharmaceutical co., ltd. was approved by the U.S. food and drug administration (FDA) and will be officially sold in 2016. This means that 3D printing will move further into the pharmaceutical industry after printing human organs. It is of great significance to realize precise pharmaceutical and targeted pharmaceutical in the future. The company's approved "left ethylasitan instant tablet" adopts the ZipDose3D printing technology of Aprecia's proprietary intellectual property rights.

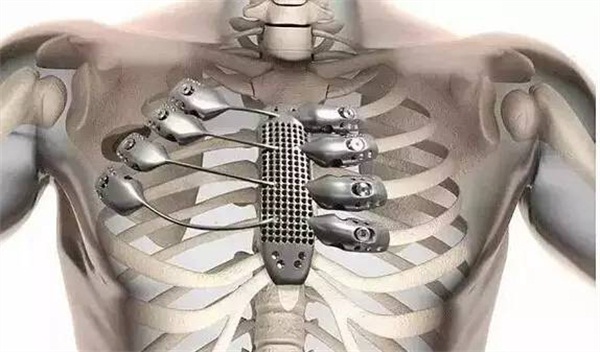

3D printing chest

Recently scientists have added a titanium sternum and chest to the traditional 3D printed body parts -- 3D printing of the thorax. The lucky recipient of these 3D printed parts was a 54-year-old Spaniard with a chest wall sarcoma. The tumor is formed in bone, soft tissue and cartilage. Doctors had to remove the patient's sternum and some ribs to stop the cancer from spreading. These resections need to be replaced. The metal plates used in normal conditions may become unstable over time and can lead to complications. The Australian company CSIRO has created a titanium sternum and rib that fits perfectly with the patient's geometry.

3D blood vessel printer

In October 2015, China's 863 planned 3D printing of blood vessel project made a breakthrough. The world's first 3D bio-blood vessel printer was successfully developed by Sichuan Blue-ray Inuo Biotechnology Co.,Ltd. The blood-vessel printer is so advanced that it can produce 250px of blood vessels in just two minutes. Different from existing 3D bio-printers on the market, the 3D bio-vascular printer can print out the unique hollow structure of the blood vessel and multi-layer different kinds of cells. This is the first in the world.

Auto Industry

On September 15, 2014, 3D printing architecture, skirt caps and jewelry appeared in the world. The first 3D printed car was finally available. The car had only 40 parts, and it took 44 hours to build, with a minimum price of 11,000 pounds. The world's first 3D printing car has been unveiled -- the tiny two-family car, designed and manufactured by Local Motors, the US company, has opened a new chapter in the car industry. The innovative product was unveiled at the international manufacturing technology exhibition in Chicago, USA, for six days.

Electronics industry

On November 10, 2014, the world's first 3D printed notebook computer was pre-sold. It allows anyone to print their own devices in their living rooms, which are only half the price of traditional products.

Apparel

Many women know that it is not easy to meet a well-fitting dress.Clothes made with a 3D printer are the key to solving the dilemma women face when choosing their clothes. A design studio has been able to use 3D printing technology to make clothes. The clothes made by this technology are not only novel, but also comfortable.