Live Review of Guoyu Garden WINSUN 3D Printing Art Landscape Park

At 2 pm on November 7, 2022, WINSUN Materials (Suzhou) Co., Ltd. (hereinafter referred to as "WINSUN") conducted a public live broadcast in Shanghai Hongqiao Guoyu Garden·3D Printing Art Landscape Park, which not only showed WINSUN The artistic, landscaped and people-benefiting urban public space demonstration park built with architectural 3D printing digital technology also announced the newly developed vehicle-mounted YC1804C (vehicle-mounted mobile cantilever printer) and YC1805 (large-scale cantilever printer) for the first time, which means With that, WINSUN's digital and intelligent 3D printing mobile factory, which can obtain local materials and print on site, has been realized!

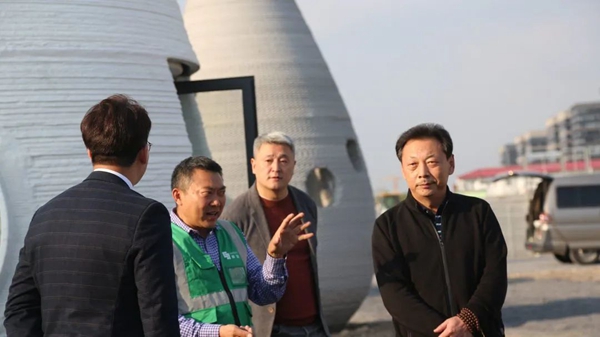

Before the official start of the live broadcast, Ma Yihe, the chairman of our company, followed the live broadcast team to repeatedly confirm the position and carefully check the camera effect. He said that WINSUN will present the best results to the audience, so that everyone can see our progress in 3D printing construction technology, breakthroughs in 3D printing smart devices, and demonstration actions in the comprehensive utilization of solid waste with high added value . Speaking of this, the chairman Ma Yihe was very excited, and he was very much looking forward to the 3D printing architecture, vehicle-mounted printers, large-scale cantilever printers and on-site printing effects that will be introduced live.

Chairman Ma Yihe walked to the on-site printing area, pointed to the working vehicle-mounted YC1804C (vehicle mobile cantilever printer) and said: "In the past architectural 3D printing technology, in specific applications, large-scale buildings need to complete structural production in factories. , and then transported to the site for hoisting, even if it is a miniaturized, integrated printing building, it has to bear high transportation costs, which was an unavoidable obstacle for WINSUN to open up the market in the past. Therefore, WINSUN began to change its thinking We want to make printers mobile, we no longer need to build factories, wherever we want projects, mobile factories can be opened, we will start to deploy in major cities, form a 3D printing 'march', let 3D Printing realizes local material collection and on-site printing, so it can be used everywhere and print everywhere!"

The vehicle-mounted YC1804C (vehicle-mounted mobile cantilever printer) placed on site is 12 meters long, with a 6-meter arm span, 4.5 meters high, and weighs 5.6 tons. YC1805 (large cantilever printer) is 12 meters long, with a 12-meter arm span and 10 meters high , weighing about 11 tons, the two printers are cantilever structures, which well make up for the inconvenient movement and poor adjustment of frame printers, and can be realized on-site from small artistic landscapes to 10-meter-high special-shaped buildings. Printing, all-in-one printing. At the same time, both devices can be transported and printed on a flatbed trailer, which is very flexible.

When asked "what exactly is a mobile factory", Chairman Ma Yihe explained that the vehicle-mounted YC1804C (vehicle mobile cantilever printer) and YC1805 (large cantilever printer) use a flatbed trailer as a transport carrier, introducing full visual coverage Such a combination is a digital and intelligent 3D printing mobile factory, which can be just one device or hundreds of devices. The advantage of the mobile factory is that it can accurately locate the location of solid waste and the location of the project, and it can be reached at any time. On-site construction can effectively avoid carbon emissions and cost increases caused by solid waste transportation and storage. At the same time, it no longer needs to build a special factory, and does not have to bear the high transportation costs of printing buildings and components. "Such a bold idea has proved its feasibility through the construction of Guoyu Garden.

In the future, WINSUN will build a super factory with 10,000 sets of 3D printing walking robots, and let digital and intelligent 3D printing mobile factories land in various cities across the country, realizing the use of industrial solid waste, mine tailings, construction waste, etc. as printing materials on the spot , on-site printing of urban furniture, creating a personalized, artistic, landscaped, and people-friendly urban living room, on-site printing of high-strength, high-efficiency, high-quality revetments, roadbeds, sound barriers, special-shaped walls and other transportation and municipal facilities, etc. Use digital technology to boost low-carbon construction and "waste-free city" construction, and use WINSUN's 3D printing mobile factory to set off another revolution in the field of 3D printing construction!

The live broadcast started, and the camera scanned the tallest 3D printed building on the scene - the 12-meter-high Gate of Light! Different from the traditional ones, this building used as the passageway for Yuyuan is like a canyon, the afternoon sunlight passes through and is reflected on the wall, and the reflections of the surrounding green branches are swaying. From here, Mr. Ma introduced us to the design concept of Yuyuan, which is to use innovative architectural 3D printing digital technology to create an art landscape park that meets people in the past. To create a relationship, I would like to meet you unexpectedly in the sea of people.

Mr. Ma said: "We hope that Guoyu Garden will be an artistic landscape park built with innovative, cutting-edge and practical digital technology such as 3D printing. It is a creative idea, and the facts have proved that this matter is feasible and promising.”

3D printing architecture is the technology of building physical buildings by gradually accumulating building materials. In the construction industry, 3D printing architecture is a kind of building that meets the construction standards and has practical functions, which is automatically and intelligently printed by machinery and equipment according to the pre-designed architectural drawing program with special printing ink. 3D printing architectural technology has brought about a revolution in the entire building system, which integrates design, construction, equipment, new materials, and application integration into a new system.

Guoyu Garden is built with architectural 3D printing digital technology, and its concept has changed from the traditional "adapt, coexist and integrate with nature" to "participate in and promote natural changes", no longer stick to the existing forms and principles, and then use A low-cost, sustainable way to realize curves and irregular shapes that were difficult to present before, and the original standardized operation system with a large number of repetitions gave way to a small-batch personalized realization.

The special-shaped buildings such as the water drop house and the egg house built by Guoyu Garden with 3D printing technology show the infinite possibilities of future architecture. In the future, the buildings built by WINSUN with 3D printing technology can be modern urban houses, new farm houses that fit the countryside, infrastructure with individual expressions, or urban landscapes with diverse aesthetics. The roads and bridges that are closely related to the needs of human survival can also be bionic landscapes tailored for the natural ecology... All in all, the future 3D printed buildings will be shaped, landscaped, and artistic, and will have infinite possibilities. Fantastic ideas, reflecting more touching humanistic feelings.

At the scene, there were many tourists who came here admiringly. During the interview session of the live broadcast host, they raised their own questions to Ma Yihe, including the selection of printing materials, the strength of materials, and heat preservation. In this regard, the general manager said that WINSUN adhered to the concept of "using technology to maximize the value of recycled resources" in the selection of materials for Guoyuyuan, and selected steel slag as the main printing raw material. During the entire construction process, the proportion can reach 85%. % or more, and these steel slags mainly come from the solid steel waste of MCC. The reason why it is possible to transform steel slag from low-value-added solid waste into high-value-added products such as special-shaped buildings and urban landscapes, and realize "turning waste into treasure" is because WINSUN has developed 156 new digital materials for solid waste recycling. Realizing the leap from C30 to C150 can meet the application requirements of various special scenarios.

The construction of Guoyu Garden shows more possibilities of 3D printing construction technology in urban public space, and it is one of the demonstrations of WINSUN's use of digital technology to promote the construction plan of "no waste city". "Technology, humanities, environmental protection and harmonious coexistence with ecology" are the core concepts of WINSUN, and WINSUN is also closely following the policy requirements of "two mountains" and "double carbon" in the new era, turning all kinds of solid waste into cementitious materials instead of cement , Sand aggregate, whether it is general industrial solid waste such as steel slag, blast furnace slag, fly ash, cinder, waste gypsum, desulfurization ash, or mining solid waste such as tailings, coal gangue and other waste rock, and even urban life solid waste The construction waste in the waste can be used as the raw material for our 3D printing. Through 3D printing technology, WINSUN uses recycled industrial solid waste, mine tailings, and construction waste to form new construction materials. Through digital design techniques, it forms a self-circulating system that provides services for cities, steel mills, power plants, and coal mines. The problem of chemical and other solid waste discharge provides innovative ideas. Relying on 3D printing construction technology and digital new material technology, it can not only absorb and digest solid waste, but also realize high value-added comprehensive utilization of solid waste by means of 3D printing special-shaped buildings and urban landscapes. , to truly realize the use of digital technology and digital materials to boost the construction of "zero-waste cities". And Guoyuyuan not only wants to show everyone the 3D printing construction technology itself, but also wants to show everyone the high value-added utilization of solid waste and multiple application scenarios, so that 3D printing construction, a new way of solid waste disposal, is widely recognized by the public. more in-depth knowledge.

The construction of Guoyu Garden is one of WINSUN's actions to promote the green and low-carbonization of the construction industry and accelerate the construction of "zero waste city". In the future, WINSUN will use digital and intelligent 3D printing mobile factories and a visualized full-coverage Internet of Things management platform to allow 3D printing robots to collect materials and print on-site at the construction site to maximize the consumption of solid waste reserves and use digital technology Boost low-carbon construction and "zero-waste city" construction.

Finally, WINSUN welcomes and sincerely invites all leaders, colleagues in the industry, and the general public to come to Yuyuan to visit and communicate, and to discuss more possibilities of architectural 3D printing digital technology and solid waste comprehensive utilization! Contribute to the early realization of the country's two-mountain and double-carbon digital economy goals.